Pattern Making:

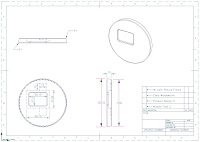

The first stage was to design the pattern to use in building the san-casting mould. I used ProDesktop 8 to design the pattern as I could use precise measurements, view the design in rendered 3D images and create an engineering drawing to use when making the pattern:

[click on images to enlarge]

The worksheet below show the basic processes involved when making the pattern:

[click image to enlarge]

Making the Sand-Casting Mould:

The following two worksheets show the process of making the sand-casting mould. This is a labour intensive process and took around an hour to prepare.

[click images to enlarge]

Casting the Aluminium:

The following worksheet shows the pouring part of the casting process.

[click image to enlarge]

The Finished Part:

[click image to enlarge]

Cutting Threads in Metal:

To attach the back panel of the cast picture frame it was necessary to cut to threaded holes into the part to receive small bolts for fixing. This involved drilling two holes using a pillar drill and a tap with wrench to cut the thread. As aluminium is a relatively soft metal this was a quick and straightforward process.

For information on metal thread cutting, click here and for more detailed information on how to use a tap and die, click here.

Reflections:

The process of sand-casting aluminium is the most advanced metal forming that we have covered on the course, more so than the pewter-made part. The stages of the process are more complex and therefore take much more time to complete. Due to the nature of the materials more specialist equipment is needed to sand-cast aluminium, the furnace in particular, compared to the relatively straightforward brazing hearth and blowtorch required for pewter. The health and safety implications are also greater with the high temperatures involved.For information on metal thread cutting, click here and for more detailed information on how to use a tap and die, click here.

Reflections:

These factors make casting aluminium much less common in schools as a way of forming metal. The time and expense involved are the main detractors; completing a sand-cast aluminium part takes several hours from start to finish (including making the pattern) whereas making a small part from pewter could potentially be achieved within one lesson if the students had knowledge of CAD/CAM for mould making. There is also a lot more work involved in cleaning up the cast aluminium; the surface after casting is quite rough and needs to be filed and sanded vigourously, adding more time to that already invested.

On the plus side, it is possible to manufacture an impressive end product and there are many cast aluminium products in everyday use to bring relevance to the process for students. There is also a good variety of skills that can be developed during the process; making the pattern involves either CAD/CAM or a range of handtool and machine skills, building the mould requires attention to detail, physical effort and correctly following ordered stages, the pouring would probably be carried out by a teacher or technician in a school scenario but is a good visual process for students to observe and cleaning up the casting uses filing and sanding skills.

On a personal level, I wouldn't rush to cast aluminium again unless it was really necessary for what I was doing (teaching the process to students, for example). The next time I cast aluminium I would like to experiment with using different materials for the pattern such as expanded foam or wax. This would change the process slightly insofar as the pattern would be left in the mould during casting and would rely on the heat of the molten metal to melt the pattern and push it out of the mould to leave just the cast metal. This is referred to as the lost wax method and is not so dependant on the pattern being perfectly made with correct draft angles and fine details that can be damaged when removing a pattern from the sand-casting mould. The downside to this is that the pattern can only be used once; fine if it is made using CAD/CAM but not really suitable for a handmade pattern, unless it is just for a one-off casting.

If a school class were to undertake an aluminium casting project, they could be set homework to research where aluminium comes from (bauxite ore) and the processes that are involved in refining it into the pure metal used in products. The ore is mined around the world so there are ecological, scientific and geographical implications that naturally lend a cross-curricular aspect to the project.

Links:

No comments:

Post a Comment